Following the recent school closures and plethora of headlines, we are seeing more and more queries about reinforced autoclaved aerated concrete (RAAC), from people wanting to know whether it is present in a building and whether it’s safe. We are hearing concerns from people in all sorts of public buildings, from schools to offices to GP surgeries. Issues around RAAC are not new, but the recent media storm has amplified concerns and heightened levels of anxiety.

What is RAAC?

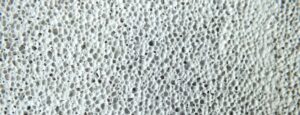

RAAC is an aerated material that was used in buildings constructed between the 1950s and 1990s. It was chosen because its bubbly texture makes it lightweight yet well-insulating. However, this same bubbly consistency reduces its strength compared with regular concrete, and makes it more susceptible to water penetration, sagging and even shearing. The construction industry has been aware of these limitations for a long time, and its use waned towards the end of the 20th century, when it became apparent that the lifespan of a RAAC panel was limited to around 30 years.

As Tim Allcott MRICS, Partner points out:

“No building materials should be expected to have an infinite lifespan, and given its particular properties, it comes as no surprise that RAAC is starting to fail. What has caught people out, is how suddenly it can happen, with little or no apparent warning.”

In 2018, a roof panel collapsed at a primary school in Kent, and in the summer of 2023, three RAAC failures in panels that had been thought not to be at imminent risk of collapse prompted government alerts, evacuation of schools and thousands of media headlines.

The need for a professional assessment

Because RAAC was used in public buildings like schools and hospitals, the potential for catastrophic consequences to its collapse is clear. What the headlines fail to mention, however, is that with proper assessment many people can be reassured that despite the presence of RAAC, their ceilings are not about to fall down around them. While it may not be obvious day-to-day that there is a problem with a RAAC panel, there are ways that building surveyors and structural engineers can determine the risk of collapse.

- Deflections, cracks and splitting puts panels and beams at high risk of collapse, as does any evidence of water contact or water leaks near the material.

- Poor design and installation is also a risk, with some panels being installed with insufficient bearing between the steel reinforcement and their supporting columns.

- Deflection can also reduce the bearing, even in panels that were orignally installed correctly.

- Roofs may have been resurfaced, or plant machinery like air conditioning units may have been added, increasing the load on the panels.

- Roofs may also have become misshapen, allowing rainwater to collect, increasing both the load and the risk of water penetration.

The government has produced a guide to identifying RAAC yourself, although the RICS recommends that an RICS chartered building surveyor or chartered structural engineer should be used to check whether RAAC is present in your building.

Should I use a surveyor or a structural engineer for a RAAC inspection?

A chartered building surveyor will carry out a visual, non-destructive RAAC inspection of the building to establish whether they believe there is any evidence of any RAAC incorporated within the building structure. Where RAAC is found (or presumed), the overall condition of the visible sections of RAAC will be assessed and reported on. A chartered building surveyor will provide advice on any remedial work or recommended precautionary measures in relation to RAAC.

As well as inspecting the RAAC itself, a surveyor will view building as a whole. They will used their experience in assessing the overall condition and maintenance of the property to look for evidence that it has been kept in a good condition, or conversely, that there are signs of poor maintenance that could lead to leaks and water penetration. They will also be considering the use of the spaces within the building, both to assess the risk posed by any RAAC, and to identify whether there is any inappropriate use of space above RAAC panels that could affect their integrity.

As Peter Mallinson MRICS, our lead RAAC surveyor, notes:

“As part of the report, we will also provide advice and estimated costs for general maintenance requirements that might impact the condition of RAAC. Given the age of the buildings affected, asbestos can sometimes be found adjacent to RAAC panels. A chartered surveyor will be aware of this possibility and will visually identify any asbestos containing materials and advise on how they would affect remedial works.”

Depending on the condition of the RAAC, a chartered structural engineer may then be needed to detail remediation, strengthening or replacement specifications. An engineer might decide to carry out intrusive investigations to check the position of the reinforcements, and carry out tests to see if there has been any corrosion. Structural engineers can also provide structural designs and calculations for strengthening measures and even for new roof structures.

Find out more about our RAAC Inspections